Shandong Blue future company begin production of Nanofiber face masks

Shandong Blue future new material Company said the new KN95 masks, which adopt nanotechnology, can be reused up to 10 times after disinfection.

It has provided guidance as the mask has been developed, including design, production and sales. Manufacturing is being done by Shandong Bluefuter new material company, located in Jinan city

The authority has pushed the manufacturers to turn out recyclable masks since there has been a shortage of melt-blown nonwovens and nonwoven cloth, the raw materials for disposable masks, it said.

The new mask, follows the KN95 standard, which is similar to the certifications for the American N95 and European FFP2. This means each mask can filter 95 per cent of particles with a mass median diameter of 0.3 micrometres.

According to the Shanghai authority, the masks have high air permeability and are waterproof. Those wearing one for a long time won’t feel their mouth turn moist, the authority said.

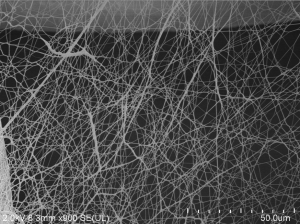

Inside the mask is a thin nanofiber membrane that can filter 95 per cent of particles as small as 0.075 micrometres in diameter. The coronavirus is about 0.1 micrometres in diameter.

The manufacturers found that the mask could maintain its filtering ability for 20 uses after being cleaned with boiling water, alcohol or 84 disinfectant liquid, although they recommend that wearers use it no more than 10 times.

The mask’s filtering ability can last for 200 hours, more than 20 times that of normal disposable masks.

“Some key indexes [of our mask] reach the standard of medical use,”"But the masks for medical use should undergo asepsis processing, while our company’s production environment does not meet that requirement. Therefore, our masks will be sold to ordinary citizens rather than medical staff.”

The committee said the production capacity was growing gradually, with a bottleneck caused by a shortage of workers to sewing the masks and a limited supply of nanometre materials. The authority said it was coordinating the supplying of raw materials and offering financial aid to the Juchen company to add more packing machines.

“It’s also not a problem for nanofiber to be recycled,” he said. “The key in producing a mask is to make sure that the both sides can cover up the face closely, without any cracks in between.”