The rise of green building material and integrate panel for outside Walls

In recent years, the development of green buildings has promoted energy-saving and environmentally friendly green building materials. Natural stone is a non renewable resource. While protecting the ecology, some materials that replace natural stone have gradually become a trend. The integrated panel for exterior wall insulation and decoration has become the main product of building exterior walls. Not only can it replace traditional exterior wall thin plastering systems and stone dry hanging, but it also takes into account the insulation and decoration effect.

- Product feature of Thermal insulation decorative integrated board:

1. Strong decorative properties

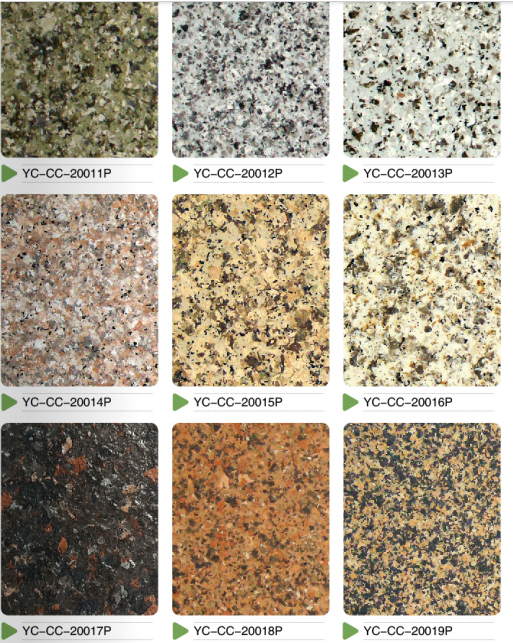

95% high imitation stone, without color difference, with strong three-dimensional sense and texture, completely comparable to natural stone, showcasing the top quality of architecture.

2. High security

From four aspects: material safety, structural safety, fire safety, and aiming safety

Build comprehensive security measures to eliminate potential safety hazards in buildings.

3. Good self-cleaning performance

The layer has good anti fouling performance, making it difficult for dust and dirt to adhere. It can be cleaned and has good self-cleaning properties, which will not affect the decorative effect.

4. Long service life

High quality raw materials and scientific production processes ensure that products have a decorative lifespan of over 25 years.

5. Strong cost-effectiveness

Realistic imitation stone effect, enhancing the taste of the real estate, with a much lower price

The price of stone curtain walls is very cost-effective.

6. Good insulation

It has excellent thermal insulation performance, low and stable thermal conductivity, and is not affected by temperature and humidity changes, making the entire building have a constant temperature effect.

7. Convenient installation

Compared with traditional aluminum panels and curtain walls, integrated panels have a lighter weight and are easy and fast to install.

- Composition and types of insulation and decoration integrated panels:

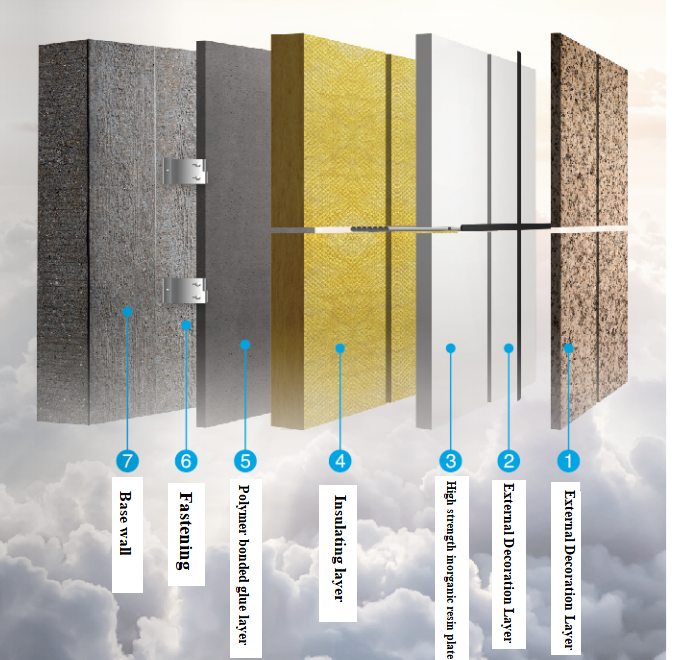

① Composition of insulation and decoration integrated board

Insulation and decoration integrated board, also known as energy-saving insulation and decoration integrated board, is mainly composed of insulation layer, substrate, decorative coating, bonding layer, anchoring parts, sealing materials, etc

The insulation layer is divided into: inorganic composite non combustible insulation board, rock wool board, graphite polystyrene board (SEPS), extruded polystyrene board (XPS), etc.

The substrate is divided into: cement pressure plate, calcium carbonate board, glass fiber resin, etc.

Decorative coatings are divided into: fluorocarbon solid color paint, fluorocarbon color printing, real stone paint, water in water, water in sand, natural stone, real stone flake paint, fluorocarbon color coated stone pattern paint, etc.

② Type

Common insulation and decoration integrated boards: ceramic thin plate insulation integrated board, imitation stone paint insulation integrated board, aluminum plate insulation integrated board, ultra-thin stone integrated board.

- Heat preservation decoration integrated board process flow

① Production process

Substrate → Sanding → Sealing Primer → Topcoat Spray → Coating → Composite → Finished Board

② Construction technology

The installation and construction process of integrated panels for external wall insulation and decoration is of utmost importance, and there are mainly two mainstream integrated installation methods: adhesive anchor combination type and dry hanging type.

- Adhesive anchoring type

According to the situation of the insulation and decoration integrated board, the insulation and decoration integrated board is first bonded to the base wall using mortar bonding method, and then anchored into the wall in the correct position, double fixing to make the insulation and decoration integrated board more firm.

- Dry hanging type

Similar to dry hanging stone, steel keel needs to be pre installed on the wall base layer. The insulation and decoration integrated board is connected to the keel through special anchoring components, and the integrated board is filled with foam polyurethane or other materials between the wall base layer.

- Application Range

1. Areas that require winter and summer insulation according to design requirements.

2. Newly built, expanded, and renovated industrial and civil buildings. For example, the exterior walls of high-end residential buildings, star rated hotels, commercial complexes, villas, office buildings, hospitals, schools, sports venues, and other buildings.